|

| April 28, 2015 | Volume 11 Issue 16 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wings:

Siemens develops world-record electric motor for aircraft

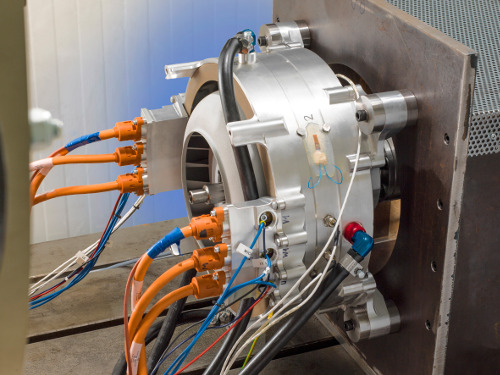

Siemens has developed an exceptional electric motor that combines high power with minimal weight, resulting in a drive system that sets a world record for power/weight ratio in its class. It's a major step toward the everyday use of electrically powered, hybrid aircraft and helicopters. [All images courtesy: Siemens]

Researchers at Siemens have developed a new type of electric motor that, with a weight of just 110 lb (50 kg), delivers a continuous output of about 260 kW -- five times more than comparable drive systems.

The motor has been specially designed for use in hybrid aircraft where the electric motors are used for high-energy-demand tasks like takeoff and climbing.

Thanks to its record-setting power-to-weight ratio, larger aircraft with takeoff weights up to 2 tons will now be able to use electric drives for the first time.

To implement the world-record motor, Siemens' experts scrutinized all the components of previous motors and optimized them up to their technical limits. New simulation techniques and sophisticated lightweight construction enabled the drive system to achieve a unique weight-to-performance ratio of 5 kW/kg.

The electric motors of comparable strength that are used in industrial applications deliver less than 1 kW/kg. The performance of the drive systems used in electric vehicles is about 2 kW/kg.

Since the new motor delivers its record-setting performance at rotational speeds of just 2,500 rpm, it can drive propellers directly, without the use of a transmission.

To implement the world-record motor, Siemens' experts scrutinized all the components of previous motors and optimized them up to their technical limits.

"This innovation will make it possible to build series hybrid-electric aircraft with four or more seats," says Frank Anton, Head of eAircraft at Siemens Corporate Technology, the company's central research unit.

The motor is scheduled to begin flight-testing before the end of 2015. In the next step, the Siemens researchers will boost output further. "We're convinced that the use of hybrid-electric drives in regional airliners with 50 to 100 passengers is a real medium-term possibility," says Anton.

The motor, specially designed for use in aircraft, is shown here being tested on a test rig.

The development of this motor was supported by the German Aviation Research Program LuFo in a project of Grob Aircraft and Siemens.

In 2013, Siemens, Airbus, and Diamond Aircraft successfully flight-tested a series hybrid-electric drive in a DA36 E-Star 2 motor glider for the first time. The test aircraft had a power output of 60 kW.

SIDEBAR

Microlights, planes go hybrid-electric

In a related development, researchers from the University of Cambridge, UK, in association with Boeing, have successfully tested the first aircraft to be powered by a parallel hybrid-electric propulsion system, where an electric motor and gasoline engine work together to drive the propeller. The test took place in December 2014. The demonstrator aircraft uses up to 30 percent less fuel than a comparable plane with a gas-only engine. The aircraft is also able to recharge its batteries in flight, which is a first.

The demonstrator is based on a commercially available single-seat aircraft, and its hybrid engine was designed and built by engineers at Cambridge with Boeing funding support.

The aircraft uses a combination of a four-stroke piston engine and an electric motor/generator, coupled through the same drive pulley to spin the propeller. During take-off and climb, when maximum power is required, the engine and motor work together to power the plane, but once cruising height is reached, the electric motor can be switched into generator mode to recharge the batteries or used in motor-assist mode to minimize fuel consumption. The same principle is at work in a hybrid car.

While the Cambridge demonstrator is an important step in the development of hybrid or fully electric aircraft, researchers have a long, long way to go before commercial airliners will be powered entirely with electric motors. For example, if all the engines and all the fuel in a modern jetliner were to be replaced by batteries today, the plane would have a total flying time of roughly 10 minutes.

Sources: Siemens, University of Cambridge (sidebar)

Published April 2015

Rate this article

View our terms of use and privacy policy